Effective Cable Shielding Tape for Enhanced Protection

By:Admin

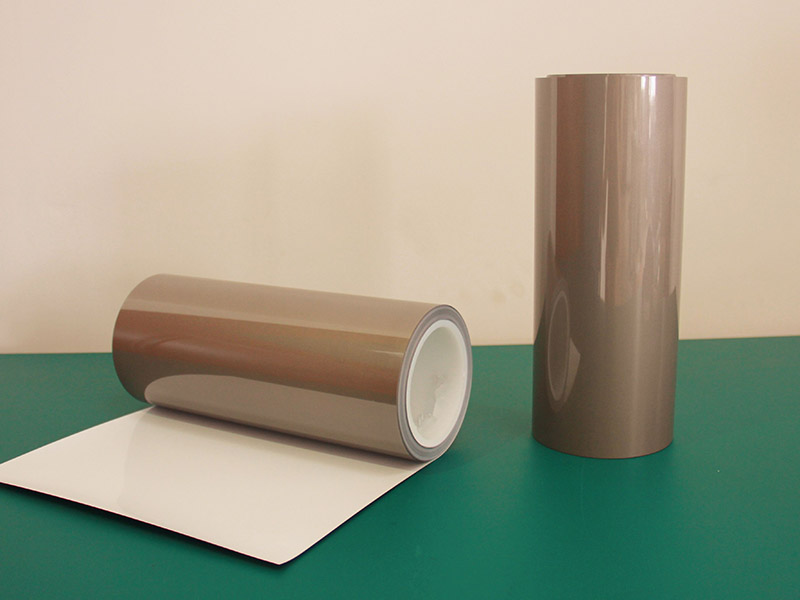

As a prominent player in the industry, Emi Cable Shielding Tape has garnered a strong reputation for its commitment to excellence and innovation. The company's extensive range of shielding tapes is designed to effectively protect cables from electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring optimal performance and reliability in various applications.

Emi Cable Shielding Tape's products are engineered to deliver superior performance and durability, thanks to the use of high-quality materials and advanced manufacturing processes. The company's state-of-the-art production facilities and stringent quality control measures ensure that every shielding tape meets the highest standards of quality and reliability.

One of the key advantages of Emi Cable Shielding Tape's products is their versatility and compatibility with a wide range of cable types and sizes. Whether it's for industrial, telecommunications, automotive, or consumer electronics applications, the company's shielding tapes are designed to provide effective protection against EMI and RFI, ensuring uninterrupted signal transmission and preventing potential interference issues.

In addition to its commitment to delivering top-notch products, Emi Cable Shielding Tape also places great emphasis on customer satisfaction and support. The company's team of experienced professionals is dedicated to providing expert guidance and assistance to customers, helping them select the most suitable shielding tape for their specific requirements and ensuring a seamless and efficient installation process.

Emi Cable Shielding Tape's comprehensive range of shielding solutions includes various adhesive and non-adhesive tapes, each offering unique features and performance benefits to address different application needs. From flexible and easy-to-apply tapes to heavy-duty options for extreme environmental conditions, the company's product portfolio caters to a diverse array of cable shielding requirements.

Furthermore, Emi Cable Shielding Tape is committed to environmental sustainability and responsible manufacturing practices. The company's products are designed to meet stringent environmental standards, and its production processes prioritize energy efficiency and waste reduction, contributing to a greener and more sustainable industry.

With a strong focus on continuous innovation and product development, Emi Cable Shielding Tape is poised to remain at the forefront of the cable shielding market. The company's ongoing investment in research and development ensures that its products continue to meet the evolving needs of the industry and deliver cutting-edge solutions to customers around the world.

In conclusion, Emi Cable Shielding Tape stands out as a trusted and reliable provider of high-performance shielding solutions for cables. With its unwavering commitment to quality, innovation, and customer satisfaction, the company is well-positioned to meet the current and future demands of the industry, solidifying its reputation as a leader in cable shielding technology.

For more information about Emi Cable Shielding Tape and its range of products, visit their official website or contact their team directly to discuss specific requirements and solutions.

Company News & Blog

Durable Foil Shielding Tape for Effective Cable Protection

Foil Shielding Tape: The Latest Innovation in EMI Shielding TechnologyIn today's fast-paced and technology-driven world, electromagnetic interference (EMI) has become a major concern for a wide range of industries. EMI can disrupt the functioning of electronic devices, leading to malfunctions, loss of data, and even system failure. As a result, companies are constantly seeking innovative solutions to protect their electronic equipment from EMI.One such solution that has been gaining attention in the industry is Foil Shielding Tape, a cutting-edge product that offers superior EMI shielding capabilities. This innovative tape is designed to provide a robust barrier against electromagnetic interference, ensuring the smooth and uninterrupted operation of electronic devices in various applications.One of the leading companies at the forefront of developing and manufacturing Foil Shielding Tape is {}. With a rich history of over 30 years in the industry, {} has established itself as a renowned supplier of high-quality EMI shielding materials. The company's commitment to excellence and innovation has enabled it to stay ahead of the curve and deliver state-of-the-art solutions to its customers.The Foil Shielding Tape offered by {} is engineered to meet the demanding requirements of modern electronics and telecommunications systems. It is constructed from high-quality materials, including a thin layer of metallic foil that provides exceptional shielding performance. The tape is also equipped with a strong adhesive backing, ensuring easy application and a secure seal on various surfaces.One of the key advantages of Foil Shielding Tape is its versatility. It can be used in a wide range of applications, including cable shielding, grounding, and EMI protection for electronic enclosures. Whether it's in aerospace, automotive, telecommunications, or consumer electronics, {}'s Foil Shielding Tape is a reliable choice for addressing EMI challenges across different industries.In addition to its superior shielding capabilities, Foil Shielding Tape offers other benefits such as excellent conductivity, flexibility, and resistance to environmental factors. These qualities make it an ideal solution for protecting electronic devices from external interference and maintaining their optimal performance under diverse operating conditions.With the increasing demand for advanced EMI shielding solutions, {} has continued to advance the development of Foil Shielding Tape to meet the evolving needs of its customers. The company invests heavily in research and development, leveraging the latest technologies and industry insights to enhance the performance and durability of its products.Furthermore, {} places a strong emphasis on quality and reliability, ensuring that its Foil Shielding Tape complies with international standards and regulations. This commitment to excellence has earned the company a solid reputation for delivering premium EMI shielding solutions that meet the highest industry standards.As the industry continues to evolve, the demand for effective EMI shielding solutions will only grow. With its cutting-edge Foil Shielding Tape and unwavering dedication to innovation, {} is well-positioned to address the complex challenges of EMI protection, providing its customers with the confidence and peace of mind that their electronic equipment is well-protected.In conclusion, Foil Shielding Tape is a game-changing innovation in EMI shielding technology, offering superior protection for electronic devices across various industries. Through its expertise and commitment to excellence, {} has emerged as a leading supplier of high-quality EMI shielding materials, providing its customers with reliable solutions to safeguard their critical electronic equipment. As the industry continues to advance, {} remains at the forefront, driving innovation and setting new benchmarks for EMI shielding performance.

New Dry Film Technology: A Breakthrough in Sensitive Material Manufacturing

Sensitive Dry Film, a revolutionary product developed by a leading company in the field of advanced materials, has been making waves in the industry. The product, which is designed to provide superior protection and performance in a variety of applications, has seen significant demand from a wide range of industries.The company behind Sensitive Dry Film, (company name), is a renowned innovator in the development of cutting-edge materials and technologies. With a strong commitment to research and development, the company has continuously pushed the boundaries of what is possible within the materials industry. Their team of experts and scientists has worked tirelessly to create products that offer exceptional performance, reliability, and value to their customers.Sensitive Dry Film is a prime example of the company's commitment to innovation and excellence. The product is a high-performance coating that can be applied to a variety of surfaces, providing a protective barrier that is resistant to wear, tear, and corrosion. It is also designed to be environmentally friendly, with a low VOC content and a non-toxic formulation.One of the key features of Sensitive Dry Film is its ability to provide superior protection in harsh environments. The product has been extensively tested and proven to withstand extreme temperatures, moisture, and chemical exposure, making it an ideal choice for use in a wide range of applications. Whether it is used in the automotive, aerospace, marine, or industrial sectors, Sensitive Dry Film has demonstrated exceptional durability and performance.In addition to its superior protection properties, Sensitive Dry Film also offers excellent adhesion and flexibility. This allows for easy application and ensures that the coating remains intact even under the most challenging conditions. This makes it a highly versatile product that can be used in a variety of ways, from protecting metal surfaces from corrosion to providing a protective barrier for electronic components.The versatility of Sensitive Dry Film has made it a popular choice among manufacturers and engineers in a variety of industries. The product has been successfully used in the automotive sector, where it has been applied to various components to provide long-lasting protection and enhanced performance. It has also been utilized in the aerospace industry, where its ability to withstand extreme temperatures and harsh conditions has made it an ideal choice for use in aircraft components.Furthermore, Sensitive Dry Film has been widely adopted in the marine industry, where its resistance to moisture and corrosion has made it an essential product for protecting boats, ships, and other marine equipment. Its ability to provide long-term protection in saltwater environments has made it a favorite among marine engineers and technicians. Additionally, the product has found applications in the industrial sector, where it has been used to protect machinery, equipment, and infrastructure from wear, tear, and chemical exposure.With its exceptional performance and versatility, Sensitive Dry Film has quickly become a go-to solution for companies and industries looking to enhance the performance and longevity of their products and equipment. The product has consistently delivered on its promise of superior protection, reliability, and value, earning the trust and confidence of customers in a wide range of sectors.Moving forward, (company name) continues to lead the way in the development of advanced materials and technologies, bringing to market innovative solutions that address the evolving needs of industries around the world. With its strong commitment to research and development, the company is well-positioned to continue delivering cutting-edge products like Sensitive Dry Film that offer exceptional performance and value to its customers.

Premium Car Interior Films: Enhance Your Vehicle's Look Today

Car Interior Film, a leading provider of high-quality automotive interior protection products, has announced the launch of their latest innovation in car interior protection technology. This new product is designed to protect the interior of vehicles from wear and tear, while also providing a stylish and modern aesthetic.The company's interior protection film is made from a durable and flexible material that is easy to install and provides long-lasting protection for the interior surfaces of cars. The film is available in a variety of colors and finishes to suit the individual preferences of car owners, and its high-quality construction ensures that it will not fade, crack, or peel over time.Car Interior Film is committed to providing innovative solutions for protecting vehicle interiors, and their latest product is a testament to their dedication to developing cutting-edge technology for the automotive industry. With this new film, car owners can rest assured that their vehicle's interior will remain in top condition, even after years of use.In addition to providing protection for car interiors, the company's film also offers a range of benefits for car owners. It is designed to resist stains, scratches, and other damage that can occur during everyday use, and can be easily cleaned with standard automotive cleaning products. This makes it an ideal choice for drivers who want to keep their vehicle looking its best, without having to spend a lot of time and effort on maintenance.Car Interior Film's commitment to quality and innovation has made them a preferred supplier for automotive protection products, and their latest offering is expected to further solidify their reputation as a leader in the industry. The company's dedication to excellence is reflected in the superior performance and durability of their products, making them the go-to choice for car owners who want to ensure the longevity and aesthetics of their vehicles.The launch of this new product comes at a time when car owners are increasingly looking for advanced solutions to protect the interior of their vehicles. With the rise of modern car interiors that feature advanced technology and high-quality materials, it is more important than ever to provide reliable protection against the everyday wear and tear that can occur in a vehicle.Car Interior Film's new product aims to address this need by offering a solution that is not only effective at protecting car interiors, but also enhances their overall appearance. This combination of protection and style makes it a practical and attractive choice for car owners who want to maintain the value and appeal of their vehicles.The company's dedication to quality and innovation is further exemplified by their commitment to environmentally friendly manufacturing processes. The film is produced using sustainable materials and methods, ensuring that it is not only effective at protecting car interiors, but also environmentally conscious.With the launch of this new product, Car Interior Film is solidifying its position as a leader in the automotive protection industry, providing car owners with innovative and effective solutions for maintaining the quality and appearance of their vehicles. As the company continues to push the boundaries of technology and design, car owners can look forward to even more advanced and stylish solutions for protecting the interiors of their vehicles.

Innovative force measurement film technology revolutionizes material testing

Force Measurement Film, a cutting-edge technology developed by a leading force measurement solutions company, has been making waves in the industry with its revolutionary applications in a wide range of fields. From automotive to aerospace, healthcare to industrial manufacturing, this innovative film has been transforming the way force and pressure are measured and analyzed.The Force Measurement Film, developed and manufactured by the company, is a thin, flexible, and highly sensitive sensor that can accurately capture and measure the distribution of force on any given surface. This technology has been proven to be invaluable in various industries where precise force and pressure measurements are critical for ensuring quality, safety, and performance.One of the key features of the Force Measurement Film is its versatility and ease of use. Unlike traditional force measurement devices, such as load cells or pressure transducers, this film can be easily applied to any surface, including curved or irregular shapes, without requiring any major modifications or adjustments. This makes it a cost-effective and efficient solution for both R&D and production applications.In the automotive industry, the Force Measurement Film has been widely adopted for various testing and quality control purposes. From evaluating the impact distribution in crash tests to analyzing the pressure distribution in engine components, this technology has proven to be an invaluable tool for ensuring the safety and reliability of vehicles.Furthermore, the aerospace industry has also benefited greatly from the use of the Force Measurement Film. By accurately measuring the distribution of force and pressure on aircraft components, engineers and researchers have been able to optimize designs, improve performance, and ensure the structural integrity of aerospace systems.In the healthcare sector, this innovative technology has been used for various medical applications, such as assessing pressure distribution in orthopedic implants, evaluating the performance of prosthetics, and developing ergonomic designs for medical devices. The ability to capture precise force and pressure data has opened up new possibilities for improving patient outcomes and enhancing the efficiency of healthcare solutions.Additionally, in industrial manufacturing, the Force Measurement Film has been instrumental in optimizing production processes, ensuring the quality of manufactured products, and improving the overall efficiency of manufacturing operations. By accurately measuring the force and pressure exerted during various manufacturing processes, companies have been able to identify areas for improvement and enhance the performance of their production systems.The company behind the Force Measurement Film has been at the forefront of force measurement technology for several decades. With a strong focus on innovation, reliability, and customer satisfaction, they have established themselves as a trusted partner for companies looking to enhance their force measurement capabilities.Their team of experienced engineers and researchers work tirelessly to develop and refine cutting-edge force measurement solutions that meet the unique needs of their customers. Through a combination of advanced technology, industry expertise, and a commitment to excellence, they have earned a reputation for delivering high-quality products that provide accurate and reliable force measurement data.The company’s dedication to continuous improvement and innovation has positioned them as a leader in the force measurement industry, with a strong track record of delivering exceptional solutions to companies around the world. With the Force Measurement Film, they have once again demonstrated their ability to push the boundaries of force measurement technology and provide their customers with unparalleled tools for enhancing their products and processes.As industries continue to evolve and demand higher levels of precision and performance, the Force Measurement Film is expected to play a crucial role in driving innovation and progress across various sectors. Whether it's improving the safety of automobiles, enhancing the efficiency of manufacturing processes, or revolutionizing medical device design, this groundbreaking technology is poised to make a lasting impact on the way force and pressure are measured and analyzed.

White Coating Substrate: What You Need to Know

PVC White Coating Substrate revolutionizes the industry with its unparalleled quality and innovative technology. This new product from {Company Name} has set a new benchmark in the field of coatings with its exceptional features and benefits.{Company Name} is a leading manufacturer and supplier in the coatings industry, with a mission to provide high-quality products to its customers. With years of expertise and experience, the company has become a trusted name in the market, known for its commitment to excellence and customer satisfaction.The brand new PVC White Coating Substrate is the result of extensive research and development at {Company Name}, aiming to address the growing demands for a superior coating solution. The substrate is designed to offer outstanding performance and durability, making it the ideal choice for a wide range of applications.One of the key features of the PVC White Coating Substrate is its exceptional adhesion properties, ensuring a strong and long-lasting bond to the surface. This makes it suitable for use in various industries, including construction, automotive, and marine. Its resistance to moisture and harsh weather conditions further adds to its appeal, making it a reliable choice for both indoor and outdoor applications.In addition to its durability, the PVC White Coating Substrate also offers excellent coverage and finish. Its smooth and even coating provides a professional look, enhancing the aesthetic appeal of the surface it is applied to. This makes it a popular choice among architects, designers, and contractors who prioritize a high-quality finish for their projects.Furthermore, the substrate is easy to apply, saving time and effort for the users. Its user-friendly nature makes it a preferred choice for professionals and DIY enthusiasts alike, providing a hassle-free application process without compromising on the quality of the finish.{Company Name} prides itself on its commitment to sustainability and environmental responsibility. The PVC White Coating Substrate is no exception, as it is designed to meet the highest environmental standards. It is free from harmful chemicals and toxins, making it a safe and eco-friendly choice for environmentally conscious consumers.With its outstanding attributes and versatile applications, the PVC White Coating Substrate has already garnered attention and accolades from customers and industry experts alike. Its introduction is set to revolutionize the coatings market, offering a superior solution that meets the diverse needs of the industry.As {Company Name} continues to expand its product line and reach, the PVC White Coating Substrate stands as a testament to the company's commitment to innovation and excellence. With its unmatched quality and performance, it has set a new standard for coatings, cementing {Company Name}'s position as a leader in the industry.For those looking for a reliable, durable, and high-quality coating solution, the PVC White Coating Substrate from {Company Name} is the answer. Its exceptional features and benefits make it a standout choice, catering to the needs of various industries and applications. As the market continues to evolve, {Company Name} remains at the forefront, providing innovative solutions that redefine the possibilities in coatings.

Advanced Insert Molding Technologies: A Complete Overview

In today's fast-paced manufacturing industry, companies are constantly seeking innovative ways to improve their production processes. Insert molding technologies are one such innovation that have revolutionized the way products are manufactured. This cutting-edge technology allows for the seamless integration of multiple components into a single, finished product. The benefits of insert molding technologies are vast, including improved product quality, reduced manufacturing time and cost, and increased design flexibility.With the rise of insert molding technologies, it is crucial for companies to stay ahead of the game and adopt these advancements in order to remain competitive in the market. One company that has successfully incorporated insert molding technologies into its manufacturing processes is {Company}. Established in 1996, {Company} has been a leading provider of plastic injection molding, precision tooling, and contract manufacturing services. With a focus on quality, innovation, and customer satisfaction, {Company} has set itself apart as a trusted partner for companies seeking high-quality manufacturing solutions.The utilization of insert molding technologies has allowed {Company} to expand its capabilities and offer its clients a wider range of manufacturing options. By combining precision tooling expertise with insert molding technologies, {Company} is able to produce complex, multi-component products with superior quality and efficiency. This has positioned {Company} as a preferred manufacturing partner for companies in various industries such as automotive, medical, consumer electronics, and more.One of the key advantages of insert molding technologies is the ability to streamline the production process by consolidating multiple components into a single, finished product. This not only reduces the number of assembly steps required but also minimizes the risk of component misalignment or failure. With {Company}'s expertise in precision tooling and insert molding, clients can expect products that are not only cost-effective but also of the highest quality.Moreover, insert molding technologies offer design flexibility, allowing for the integration of various materials and components into a single product. {Company}'s engineering team works closely with clients to optimize their product designs for insert molding, ensuring that the end result meets performance requirements, aesthetic standards, and cost-effectiveness. This collaborative approach has proven to be instrumental in helping {Company}'s clients bring their innovative products to market with speed and efficiency.In addition to the manufacturing advantages of insert molding technologies, {Company} utilizes environmentally friendly materials and processes, minimizing the environmental impact of its manufacturing operations. By embracing sustainable practices, {Company} not only meets the growing demand for eco-friendly products but also contributes to a greener future for the manufacturing industry.With a clear commitment to quality, innovation, and sustainability, {Company} stands out as a leader in the integration of insert molding technologies into its manufacturing processes. By continually investing in cutting-edge technologies and expanding its capabilities, {Company} is well-positioned to meet the evolving needs of its clients and the industry as a whole.In conclusion, the adoption of insert molding technologies has transformed the manufacturing landscape, offering numerous benefits to companies worldwide. {Company}, with its forward-thinking approach and expertise in precision tooling, has successfully leveraged insert molding technologies to provide its clients with high-quality, cost-effective manufacturing solutions. As the manufacturing industry continues to evolve, {Company} remains committed to being at the forefront of innovation, ensuring that its clients can achieve their goals with efficiency, quality, and sustainability.

New Study Reveals Key Findings on Pressure Distribution

Pressure Distribution Paper Enhancing Comfort and Performance in IndustriesIn the fast-paced world of industrial production and manufacturing, the need for precise and reliable tools and equipment is paramount. With the aim of advancing the technology and processes necessary to meet this demand, a leading provider in the industry has introduced a groundbreaking product known as Pressure Distribution Paper.Pressure Distribution Paper is a cutting-edge technology designed to enhance comfort and performance in various industries, including automotive, aerospace, manufacturing, and healthcare. By accurately measuring pressure distribution between two contacting surfaces, this innovative paper is revolutionizing the way engineers and technicians evaluate the performance of their products and equipment.This state-of-the-art product is equipped with advanced sensors and proprietary software, allowing for precise and real-time data collection and analysis. The Pressure Distribution Paper enables engineers to identify pressure points, measure and visualize pressure distribution, and optimize product designs for improved performance and comfort.With a wide range of applications, Pressure Distribution Paper has the potential to transform the way industries approach product development, quality control, and performance optimization. From automotive seating and patient support surfaces in healthcare facilities to assembly line fixtures and aerospace components, this revolutionary technology is establishing new standards for comfort and performance in industrial settings.The company behind Pressure Distribution Paper, {} has been a leader in the industry for over two decades, providing innovative solutions for complex engineering challenges. With a team of dedicated experts and a commitment to excellence, the company has built a reputation for delivering high-quality products and unparalleled customer support.{} has a proven track record of developing cutting-edge technologies that have had a significant impact on various industries. With a focus on research and development, the company continues to push the boundaries of innovation, striving to create solutions that meet the evolving needs of its clients.The introduction of Pressure Distribution Paper is a testament to {}'s commitment to advancing the capabilities of industries through technology. By enabling engineers and technicians to more effectively measure and analyze pressure distribution, this product has the potential to improve the quality, reliability, and performance of a wide range of industrial products and equipment.The groundbreaking technology offered by {} is not only a testament to the company's expertise and dedication to innovation, but it also represents a significant advancement for the industries it serves. As a result, Pressure Distribution Paper is poised to become an essential tool for engineers, designers, and quality control professionals seeking to optimize the comfort and performance of their products.With its proven track record and dedication to excellence, {} is well positioned to continue leading the way in developing cutting-edge solutions for the industrial sector. As the demand for precise and reliable tools and equipment continues to grow, Pressure Distribution Paper stands out as a game-changing technology that has the potential to redefine standards for comfort and performance across various industries.

Innovative Color Changing Pressure Film: A Breakthrough in Material Technology

Color Changing Pressure Film: Revolutionary Technology for Pressure MeasurementPressure measurement is a critical aspect of various industries such as manufacturing, automotive, aerospace, and healthcare. Accurate and real-time pressure monitoring is essential for ensuring the safety and efficiency of processes and equipment. Traditional pressure sensors and gauges have been the go-to solution for pressure measurement, but advancements in technology have led to the development of innovative and more efficient solutions.One such revolutionary technology that is changing the game in pressure measurement is the Color Changing Pressure Film, developed by a leading company in the field of pressure sensing technology. This innovative film is set to revolutionize pressure measurement by providing a simple, cost-effective, and highly accurate solution for a wide range of applications.The Color Changing Pressure Film is a thin, flexible film that changes color in response to variations in pressure. The film is designed to be easily applied to the surface of any object or equipment that requires pressure monitoring. When pressure is applied to the film, it undergoes a color change that corresponds to the magnitude of the pressure exerted. This color change can be easily captured and analyzed using specialized software, providing real-time pressure data with exceptional accuracy.The film's ability to visually indicate pressure variations eliminates the need for complex and expensive equipment, making it an ideal solution for various industries. Its ease of use and versatility make it suitable for applications such as quality control in manufacturing, tire pressure monitoring in the automotive industry, and pressure mapping in healthcare for assessing patients' pressure distribution and relieving pressure sores.The company behind the development of the Color Changing Pressure Film is a leader in pressure sensing technology, with a strong focus on research and innovation. The company has a proven track record of developing cutting-edge pressure sensing solutions that have been widely adopted across different industries. Their commitment to precision, reliability, and performance has made them a trusted partner for businesses looking for advanced pressure measurement solutions.One of the key features of the Color Changing Pressure Film is its ability to provide quantitative pressure data with high spatial resolution. This means that the film can accurately measure pressure distribution across a surface, allowing for detailed analysis and optimization of pressure-related processes. Its high sensitivity and repeatability make it a valuable tool for research and development, as well as for quality control and troubleshooting in various industries.In addition to its technical capabilities, the film's cost-effectiveness and ease of use make it an attractive alternative to traditional pressure sensors and gauges. Its simple application process and compatibility with standard imaging equipment make it accessible to a wide range of users, from small businesses to large corporations.The company behind the Color Changing Pressure Film is dedicated to providing comprehensive support to its customers, including technical assistance, customization options, and training programs. They understand the diverse needs of different industries and are committed to delivering tailored solutions that meet specific requirements.The Color Changing Pressure Film is a prime example of how innovation in pressure sensing technology is driving progress and efficiency across industries. Its potential to revolutionize pressure measurement and monitoring is a testament to the power of technology to transform traditional practices and enable new possibilities.As industries continue to evolve and demand higher levels of precision and efficiency, the Color Changing Pressure Film stands out as a game-changing solution that is poised to make a significant impact. Its ability to provide accurate, real-time pressure data in a simple and cost-effective manner positions it as a key player in the future of pressure measurement technology.

High-Quality Photosensitive Film PCB for Your Electronics Needs

Photosensitive Film PCB, a groundbreaking innovation in the field of printed circuit boards, has been making waves in the electronics industry with its cutting-edge technology. This revolutionary product has been developed by a leading company specializing in electronics manufacturing, aiming to provide a solution that meets the demands of modern electronic devices.The photosensitive film PCB is a key component in the manufacturing process of printed circuit boards, which are essential for the functioning of electronic devices. This new technology offers an efficient and reliable solution for creating intricate circuit patterns with high precision and accuracy. It has the capability to produce fine lines and spaces, enabling the production of complex and densely packed PCB designs.One of the key benefits of the photosensitive film PCB is its ability to reduce production time and costs. Traditional methods of PCB production often involve multiple steps and processes, which can be time-consuming and labor-intensive. With the introduction of this innovative technology, manufacturers can now streamline their production process and improve efficiency, resulting in cost savings and increased productivity.In addition, the photosensitive film PCB offers improved performance and reliability. Its advanced material composition and manufacturing process ensure that the final product meets stringent industry standards for quality and durability. This makes it an ideal choice for a wide range of electronic applications, including consumer electronics, industrial equipment, medical devices, and more.Furthermore, the company behind the development of this groundbreaking technology has a strong track record of innovation and excellence in the field of electronics manufacturing. With a team of experienced engineers and technicians, the company is dedicated to pushing the boundaries of technology and delivering cutting-edge solutions to its customers.The company has invested heavily in research and development to bring the photosensitive film PCB to market, and their efforts have paid off with the successful commercialization of this game-changing product. They have also established strategic partnerships with key players in the electronics industry to ensure the widespread adoption and integration of this technology into various electronic devices and applications.Moreover, the company is committed to environmental sustainability, and the photosensitive film PCB is designed to be eco-friendly and compliant with global regulations for hazardous substances. This demonstrates the company's responsibility towards the environment and its dedication to creating innovative solutions that are both efficient and environmentally conscious.Overall, the introduction of the photosensitive film PCB represents a significant advancement in the field of electronics manufacturing, and it is expected to have a profound impact on the industry. With its superior performance, efficiency, and reliability, this innovative technology is poised to become a key enabler for the development of next-generation electronic devices, paving the way for a more connected and technologically advanced future.

New Film Measures Force Distribution for Improved Product Testing

Force Distribution Measurement Film, a groundbreaking technology developed by a leading materials science company, is set to revolutionize the way we measure and analyze force distribution in a multitude of applications. This innovative film provides a real-time, visual representation of force distribution, allowing for precise and accurate measurements in various industries such as automotive, aerospace, sports equipment, medical devices, and consumer electronics.The Force Distribution Measurement Film is a thin, flexible material that can be easily applied to a variety of surfaces to measure and analyze force distribution. This technology contains a grid of sensors that can detect and record the distribution of force when pressure is applied to the film. The data captured by the film can then be analyzed to gain valuable insights into how force is distributed across a particular surface, which can be crucial in design and manufacturing processes.One of the key features of this technology is its ability to provide real-time feedback on force distribution, allowing for immediate adjustments and improvements to be made. This is particularly beneficial in industries such as automotive and aerospace, where precise force distribution is critical for the performance and safety of parts and components.In the automotive industry, for example, the Force Distribution Measurement Film can be used to analyze the force distribution on a car seat, steering wheel, or brake pedal. This data can help engineers and designers understand how force is distributed during various driving scenarios, leading to the development of more ergonomic and comfortable vehicle interiors.Similarly, in the aerospace industry, this technology can be utilized to analyze the force distribution on aircraft seats, control panels, and other critical components. By having a clear understanding of how force is distributed, manufacturers can optimize the design and construction of these components for improved performance and safety.Furthermore, the Force Distribution Measurement Film has applications in the development of sports equipment, such as helmets, padding, and footwear. By using this technology, sports equipment manufacturers can gain crucial insights into how force is distributed upon impact, leading to the design of safer and more efficient products.In the medical device industry, this technology can be used to analyze force distribution in prosthetics, orthotics, and rehabilitation equipment. Understanding how force is distributed can lead to the development of more comfortable and effective medical devices that improve the quality of life for patients.Moreover, the Force Distribution Measurement Film can also be applied to consumer electronics, such as smartphones, tablets, and wearable devices. By analyzing force distribution on the surfaces of these products, manufacturers can improve the durability and usability of their devices, creating more reliable and user-friendly products for consumers.The company behind this cutting-edge technology, {} is a global leader in materials science, with a strong track record of developing innovative solutions for a wide range of industries. Their expertise in materials engineering and technology development has enabled them to create the Force Distribution Measurement Film, which has the potential to significantly impact the way force distribution is analyzed and measured across various applications.With a commitment to pushing the boundaries of materials science and engineering, {} continues to lead the way in developing technologies that improve performance, safety, and usability in a variety of industries. The Force Distribution Measurement Film is just one example of their dedication to innovation and their ability to provide practical solutions that address real-world challenges.As industries continue to push the boundaries of performance and safety, the demand for technologies that can accurately measure and analyze force distribution will only continue to grow. The Force Distribution Measurement Film, developed by {}, represents a significant advancement in this field, offering a versatile and effective solution for gaining valuable insights into force distribution in a wide range of applications.